Artifacts To Date:

I worked this week to rebuild my Scratch prototypes with the Processing language, which is best for creating graphics that can be translated into textiles on a jacquard loom. WOVNS requires all colors to be expressed with specific hexadecimal values in any selected palette. Coding with that kind of color specificity is not possible with Scratch.

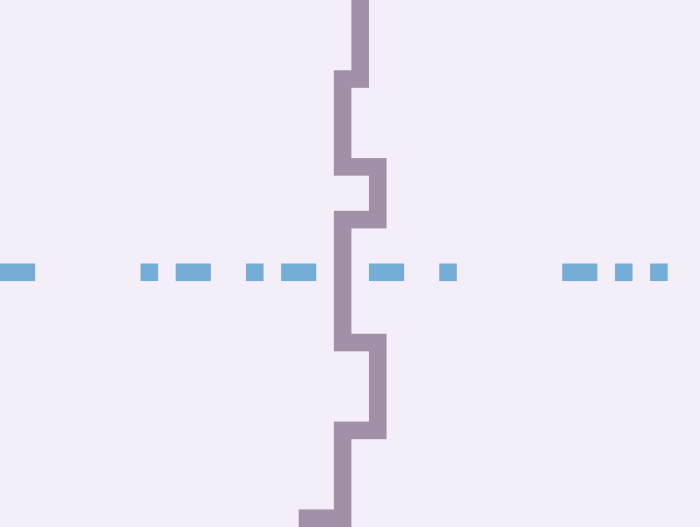

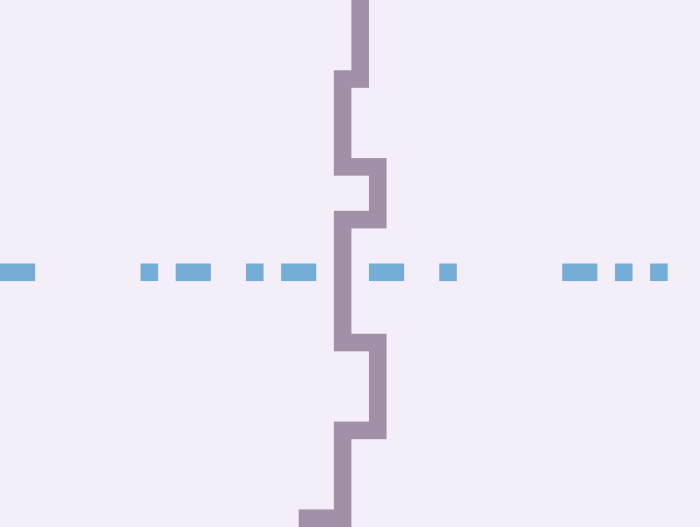

The first rebuild used a different algorithm to achieve the desired generative design. Here is an example generative design:

Here is the code:

// "Two Agents Crossing" Dylan Ryder, November 2017

// Designed in Processing

// Talma Quality, Pastel 2 Palette

size(3984, 3000); // 46-48" x 36", 84 DPI

background(#F9FAF9); // Blizzard

noSmooth();

noStroke();

int side = 100;

int x1 = 2000;

int x2 = 0;

int y1 = -100;

int y2 = height / 2;

// Vertical Agent

fill(#877193); // Beta

while (y1 < height) {

// Y axis traveling

int r = int(random(7));

for (int i = 0; i <= r; i++) {

y1 += side;

rect(x1, y1, side, side);

}

// X axis traveling

r = int(random(3));

int shift = int(random(2));

for (int i = 0; i < r; i++) {

if (shift == 0) {

x1 -= side;

rect(x1, y1, side, side);

} else {

x1 += side;

rect(x1, y1, side, side);

}

}

}

// Horizontal Agent

for (int x = 0; x < width; x += side) {

pushMatrix();

translate(x * int(random(2)), 0);

fill(#BFCDE5); // Moon

//fill(#74AED7); // Ciel

rect(x2, y2, side, side);

popMatrix();

}

// generate a unique filename for each generation based on datestamp

save("Form "+nf(month(), 2)+"-"+nf(day(), 2)+"-"+year()+" at "+nf(hour(), 2)+"."+nf(minute(), 2)+"."+nf(second(), 2)+"s"+".png");

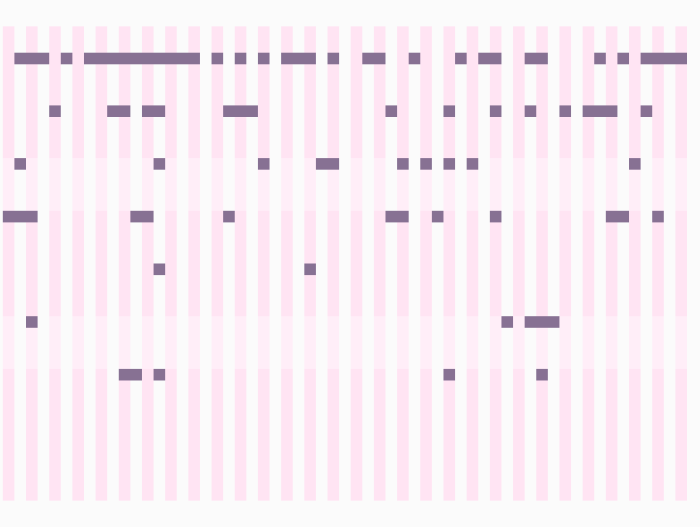

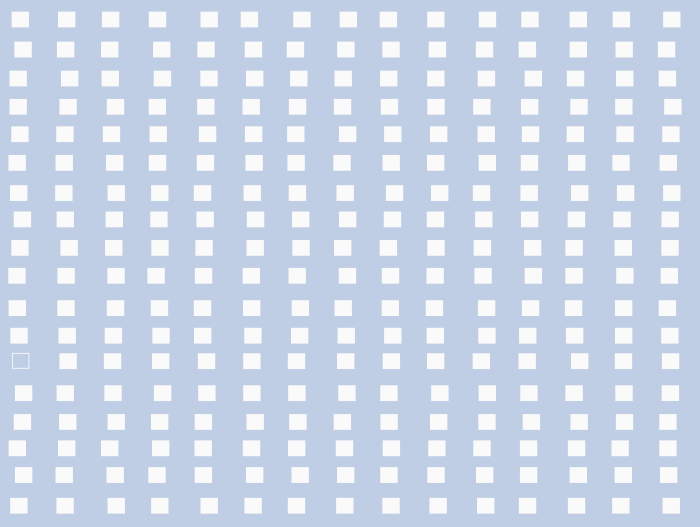

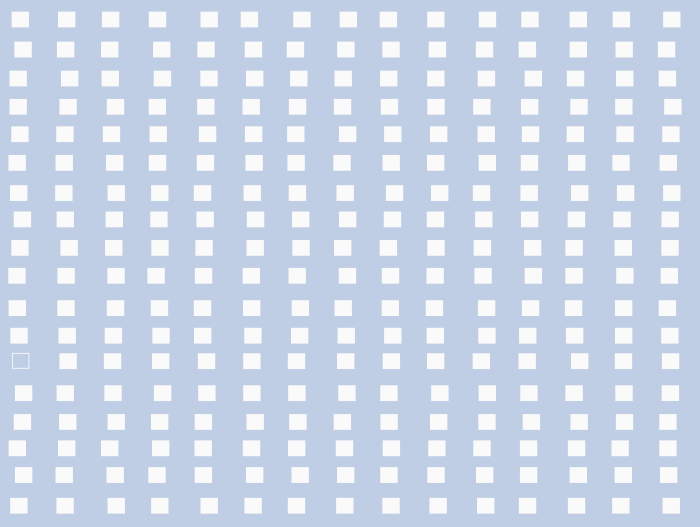

The next rebuild also used a slightly different algorithm to achieve my desired generative design. Here is an example of that generative design:

Here is the code:

// "Squares in an Imperfect Grid with 8-bit Fill Variability"

// Dylan Ryder, November 2017

// Designed in Processing

// Talma Quality, Pastel 2 Palette

size(3984, 3000); // 46-48" x 36", 84 DPI

background(#BFCDE5); // Moon

noSmooth();

noStroke();

color c = #F9FAF9; // Blizzard

fill(c);

int w = width / 30;

int h = height / 25;

int r; // horizontal random gap between squares

int vRand; // vertical random gap between rows

int stroke;

for (int row = 0; row < 18; row++) {

vRand = int(random(30));

for (int col = 0; col < 18; col++) {

// decide if the shape is filled or not

if (int(random(256)) == 255) {

noFill();

stroke(c); // Color

stroke = 5;

strokeWeight(stroke);

} else {

noStroke();

fill(c); // Color

stroke = 0;

}

r = int(random(-20, 20));

// draw the square

rect(w * col * 2 + w / 2 + r, h * row * 1.35 + h / 2 + vRand,

(w * 3 / 4)-stroke, (h * 3 / 4)-stroke );

}

}

// generate a unique filename for each generation based on datestamp

save("Grid "+nf(month(), 2)+"-"+nf(day(), 2)+"-"+year()+" at "+nf(hour(), 2)+"."+nf(minute(), 2)+"."+nf(second(), 2)+"s"+".png");

Adjustments to Timeline:

I am feeling motivated to make this work a triad and plan to design one more algorithm for a third piece. I plan to get that done this weekend and if I am satisfied with it, I will have all three works fabricated.

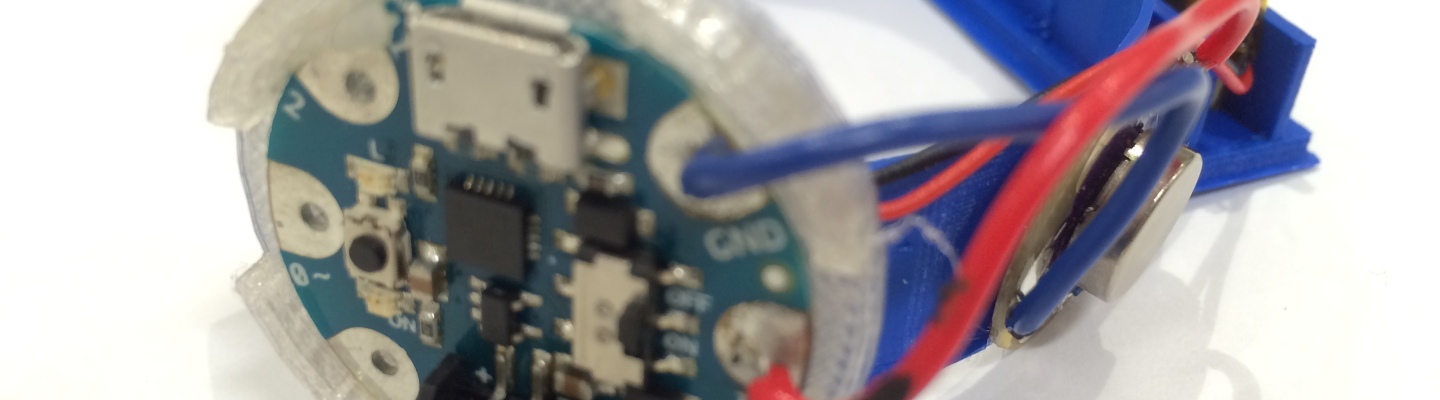

The prototypes require another thin layer of cured silicone to seal the air chamber, which is welded together with a final thin coat of liquid silicone. Regardless, still had a few air leaks, which I attempted to seal with silicone caulking sealant. I’m not use that they are chemically the same, or will bond permanently, but it is a chore to mix new batches of silicone repeatedly, so I took a chance.

The prototypes require another thin layer of cured silicone to seal the air chamber, which is welded together with a final thin coat of liquid silicone. Regardless, still had a few air leaks, which I attempted to seal with silicone caulking sealant. I’m not use that they are chemically the same, or will bond permanently, but it is a chore to mix new batches of silicone repeatedly, so I took a chance.